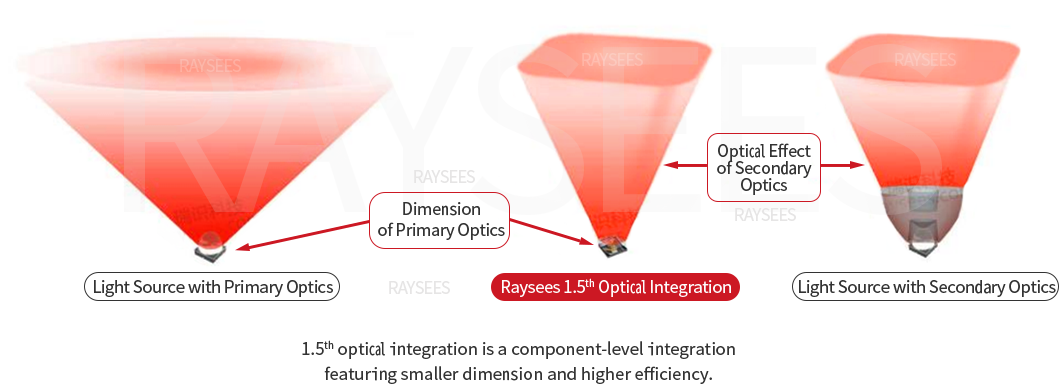

Optical Integration

Compared with conventional optical integration, 1.5th optical integration is a component-level integration featuring smaller dimension and higher efficiency.

Technical Highlights of 1.5th Optical Integration

More adaptability to customer demand

Light sources complimented by Raysees 1.5th optics packaging technique offers a wide range of benefits to 3D optical sensing applications requiring flood illumination, such as smart security, face recognition, and biometric identification. Raysees aim is to bring revolutionary change and progress to 3D face recognition devices using structured light technology, on both cost reduction and performance enhancement.

Size and cost reduction

1.5th optical integration technology works effectively as conventional primary and also secondary optics. The package size is considerably reduced which makes it more suitable for the development of smaller sized consumer electronics. The reduced packaging size efficiently decreases the usage of packaging materials and also reduces the packaging workload, thereby systematically decreasing the cost of the light source products. In addition, there is cost savings from optical lens is aligned to source at component level therebyplaying an effective role in saving excessive cost due to extra equipment and product defect rate.

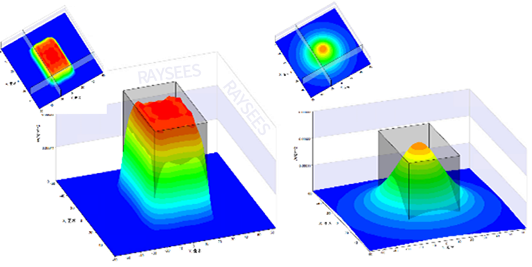

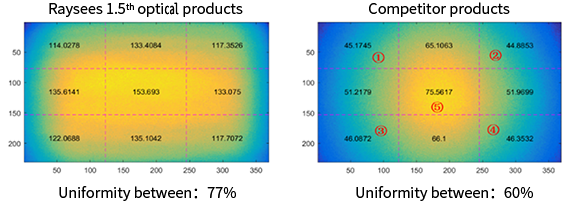

Comparison of intensity, beam shape and uniformity between Raysees 1.5th optical products (left) and competitor products (right).

.svg)